Modern farm equipment plays a prominent role in ensuring efficiency and yields in the agriculture sector. From your tractor to your planters and sprayers, maintaining each piece of machinery is essential in ensuring productivity.

Proper equipment maintenance is vital to keep your operations running and helps extend the life of your farm equipment. A crucial part of that is creating a robust maintenance plan that helps prevent costly breakdowns and keeps your work assets in tip-top shape.

Benefits of Implementing a Robust Farm Equipment Maintenance Plan

Modern agriculture revolves around the peak performance of farming equipment. As such, every farmer should be familiar with the reasons why equipment needs to be maintained regularly.

Other benefits of regular maintenance include:

- Decreased instances of equipment breakdown

- Efficient equipment management

- Improved reliability

- Extended equipment life

- Higher Resale Value

Tips to Protect Your Agriculture Equipment

There are a couple of measures you can take to ensure your equipment is well taken care of and continues to function optimally. Below, we’ll delve into some useful tips to enhance the lifespan of your valuable farm equipment.

Prepare an Equipment Maintenance Plan

Protect your farm’s largest investments by developing a robust maintenance plan that contains all your equipment maintenance activities and a schedule for when those tasks need to be completed. Here’s what this would look like:

Pre-Planting Maintenance

- Thoroughly inspect all your equipment and look for signs of wear and damage on belts, chains, hoses, and other moving parts.

- Tighten loose connections and replace worn clamps and screws.

- Check your tires if they have enough air and are properly inflated.

- Inspect your wheel bearings to make sure they are ready for use.

- Assess the condition of your battery. Look for signs of corrosion and test its strength to determine whether it needs to be replaced.

- Test your lights, signals, and hazards to ensure they can provide proper illumination during nighttime planting sessions.

- Examine the engine and check its fluid and coolant levels. Look for signs of leaks, especially after winter has passed.

Pre-Harvest Maintenance

- Clean all harvest equipment thoroughly. Remove any debris lodged between moving parts to eliminate fire hazards and potential causes of breakdowns.

- Check your belts, filters, and hoses during fuel stops and look for signs of damage to see if they need replacing.

- Pay attention to fluid levels such as oils and lubricants to ensure that your engines are kept cool during harvest operations. If you bought a new tractor, change the oil and filters after the first 50 hours of use and every 100 hours after that.

- Prepare for possible fires by ensuring that all fire extinguishers are charged and in good working order.

Off-Season Maintenance

- Clean your equipment from dirt and mud before storage. Spray with a rust inhibitor to prevent rust from forming.

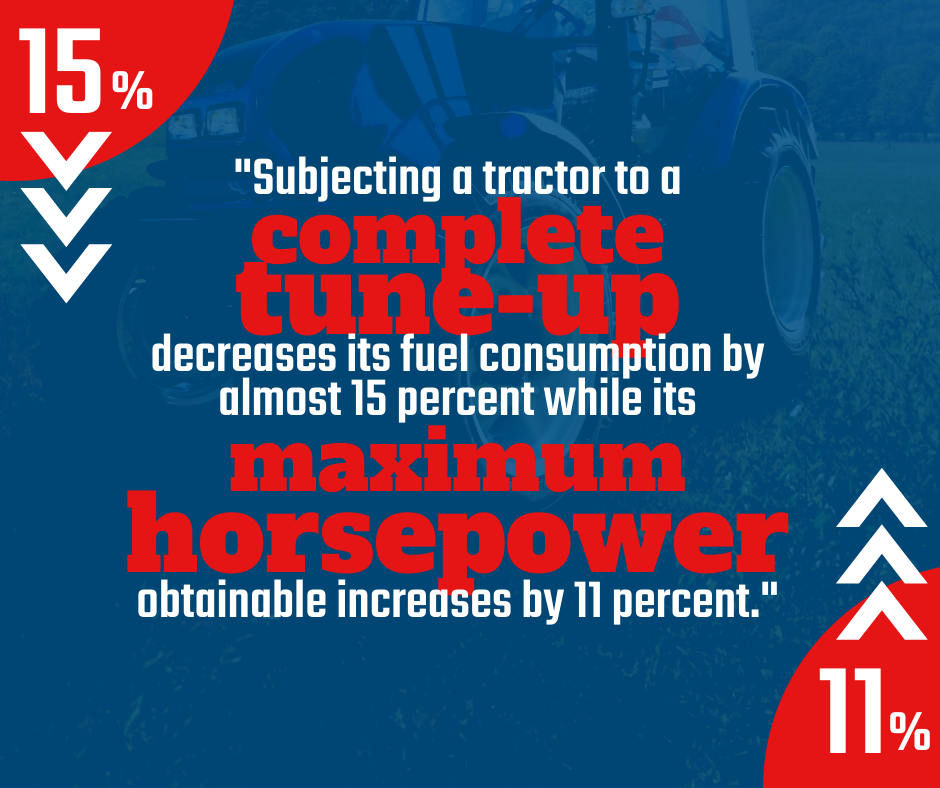

- Contact your local dealership to schedule an annual tune-up for all your equipment.

Routine maintenance should be performed regularly to detect potential problems and eliminate potential costly breakdowns in the future. Create a schedule and stick to it to keep your equipment in optimum condition until the start of the next planting season.

Be Proactive in Equipment Maintenance

Aside from your scheduled activities, it’s also essential to take a proactive approach to maintenance. This means inspecting your equipment before and after usage and solving issues that arise on the spot.

- Keep Machinery Clean. It can be challenging to tackle issues with your equipment when dirty. Keep your machinery clean by removing mud, cleaning the filters, and vacuuming the inside to keep it fresh. This also helps to avoid debris from lodging into other moving parts, which can cause problems later on while on the field.

- Lubricate Your Equipment. All moving parts should be cleaned and well-lubricated to reduce friction and ensure they are free to move without generating much heat. Use high-quality lubricant to eliminate buildup and ensure smooth operation.

- Look For Signs of Wear and Damage. Knowing your machine well is essential to spot irregularities in the way it functions. Irregular vibrations, loud noises, and overheating indicate that something is wrong that needs to be addressed immediately. For instance, hissing may indicate a punctured tire and must be sealed at once. Significant issues will need to be serviced as soon as possible.

Create a Maintenance Log

Keep track of all vehicles that need to be serviced and all other maintenance activities by keeping a maintenance log. The log will contain all information about equipment, such as issues encountered, last time servicing was performed, and when it is up for inspection.

The log will also contain information on operators in charge of the equipment and maintenance. In doing so, you can keep track of how the equipment is used and maintained, ensuring accountability across your organization.

Choose the Highest Quality Products For Proper Maintenance

Proper care and maintenance protect your equipment from damage, which ensures its longevity and preserves your investment.

It’s also important to select high-quality products to help sustain your equipment for years to come. With this, agriculture industry leaders trust Berryman Products for durable, innovative and expertly-crafted auto care products. Find a retailer near you.